Automated Storage & Retrieval Systems

At Randex we recognize that one size does not fit all and that you need a system to meet your exact needs. Whatever your storage application requires Randex is able to provide the solution for your needs.

Picking speed

Our vertical storage and retrieval systems are based on goods-to-person principles, the operator selects the required parts/goods and the machine will deliver these goods at an ergonomic height where the goods can be picked. With Compact TWIN, while the operator is picking from one tray, the elevator is already on the way to fetch the item, significantly reducing any waiting time. One operator can achieve a greater number of picks per hour and massively reduce picking errors.

Space-saving

Compact Vertical Storage Lifts store your items vertically, securely and in a controlled environment. We have a range of machine models (widths and depths) and we are able to specify machine heights in 150mm increments allowing us to maximise the storage available on any given footprint. You can save 70-90% of the floor space compared to standard racks.

Ergonomics

When the goods are stored in a Compact vertical storage lift the requested item is delivered quickly to the operator, goods are delivered on a tray at a comfortable working height. This avoids unnecessary travel distance associated with walking along static shelving or picking aisles searching for materials. A great deal of time and processes can saved compared to a traditional warehousing. In addition, the better ergonomics and working environment has a direct impact on reducing sick leave.

Versatile storage

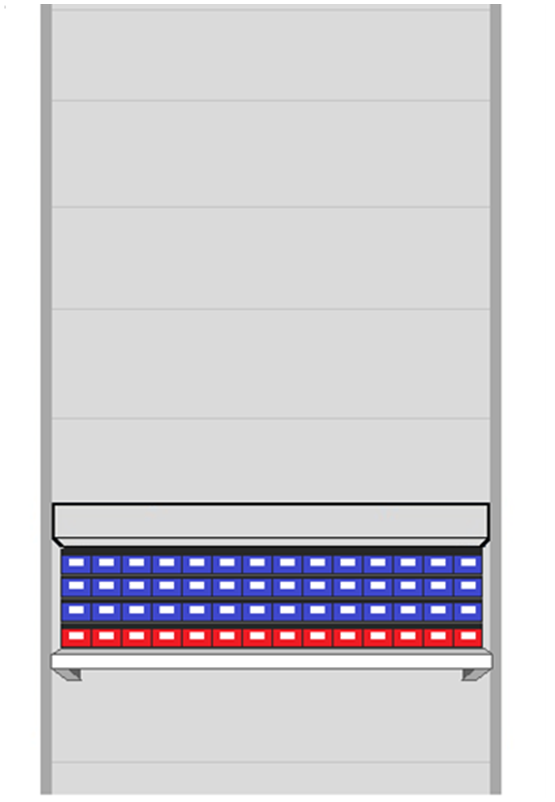

Compact vertical storage lifts are designed according to the type of goods to be stored. Everything from small parts and screws to long pipes, large plates or machine parts with a weight up to 1.5 metric tonnes per load tray. All stored compactly and safely.

Reliable operation

Compact vertical storage lifts are uniquely reliable, all machine designs are based on the 4-wheel drive rack and pinion drive system. The gear racks run the height of the machine with a pinion wheel and support wheel gripping the elevator in position on all 4 corners of the elevator. This allows us to ensure all trays movements are at the correct height regardless of whether the machine is handling a light loads or 1500KG, whether 1.2m wide trays or 6.4m wide!!

ROI - Return on investment

Many of our customers have been pleasantly surprised at how quickly the investment in a vertical storage lift pays for itself. It is not uncommon that our customers have been able to recoup the investment in a single year. Contact our sales team and we will calculate your project.