Could you save space with a vertical lift setup in your warehouse?

Space is one of the most significant costs for any warehouse. However, thanks to innovation in warehouse equipment there are optimisation solutions available. A vertical lift, for example, has a range of benefits and is essential if you’re looking to focus on space utilisation.

How a vertical lift setup could help you save space

A vertical lift setup has been designed for maximum space efficiency. It can help even the smallest of setups to find a little more room.

The design delivers highest available storage density

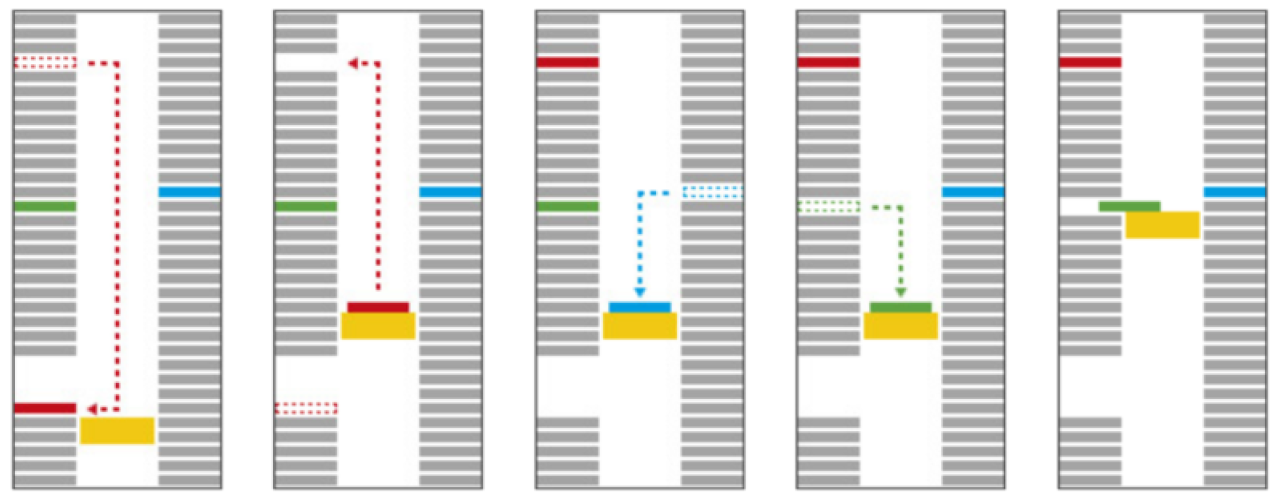

A vertical lift setup uses trays and rails to provide the best possible level of storage for the space available. Where new items of different sizes are added, the system can automatically re-slot to take into account the change in need.

Optimising the space available

Very few warehouses make full use of all available space, especially when it comes to vertical space. A vertical lift can optimise every available inch of space, as it can be specified within 1" of ceiling height.

Maximum space, minimum footprint

Although it’s possible to achieve a much higher storage density per area with a vertical lift setup, the footprint remains minimal thanks to the vertical design.

What other benefits are there to a vertical lift setup?

Reducing staff costs

The element of automation involved in this type of set up makes it possible to cut staff overheads, streamline processes and improve accuracy.

More control over inventory

With stock stored in a more confined area, a vertical lift setup provides greater control over inventory. Staff don’t have to travel between areas to find items and picking can be optimised thanks to automated and computer driven processes.

Staff productivity

Using a vertical lift set up has a very positive impact on productivity. In fact, it has been found to improve productivity by 200-400%. Staff are not only able to pick more because there is less waiting time between picks and all the items are in one place, but physical exertion from bending or reaching is reduced too. The result is greater productivity thanks to the automated support.

Accuracy

Various features integrated into a vertical lift setup can be used to improve accuracy of workflow. For example, pick-to-light systems make it much easier to avoid mistakes with orders, as the picking choices are computer controlled.

Security

Vertical units are completely enclosed and access is via password. So, security is more reliable than for open boxes or shelves and it’s possible to track, via logins, who has accessed the unit, and when.

Health and safety

Heavy items are delivered at ergonomically correct heights and tray level can be adjust to suit different operators. As bending and reaching are eliminated, risks from injury are reduced too.

There are many ways to save space by integrating a vertical lift setup into your warehouse, as well as a range of other benefits that can improve performance and productivity.